Care of ATV-Valves

ATV-Valve-System

Only these Miraphone brass instruments are equipped with the ATV-Valve-System.

- Baritone Model 54L

- Fluegelhorn Model 24R and Model 25

- Trumpet Model 9R and Model 11

The following care and maintenance instructions are valid only for instruments with ATV-Valves:

A rotary valve instrument that is in frequent use, does not usually need to be oiled. Should the instrument sit for a longer

period of time without being played, the valves should then be oiled to prevent them from freezing up.

In this case, rinse the instrument with lukewarm water and then simply put a few drops of ![]() into and through the second valve in the valve section. Spread the oil into the valve by tipping the instrument and simultaneously operating the valve keys. Be sure not to wash slide grease into the valve section with the fast oil. Valve bearings, however, should be oiled at regular intervals (as described as follows).

into and through the second valve in the valve section. Spread the oil into the valve by tipping the instrument and simultaneously operating the valve keys. Be sure not to wash slide grease into the valve section with the fast oil. Valve bearings, however, should be oiled at regular intervals (as described as follows).

Lubricating ATV-Valves on the bearing pin

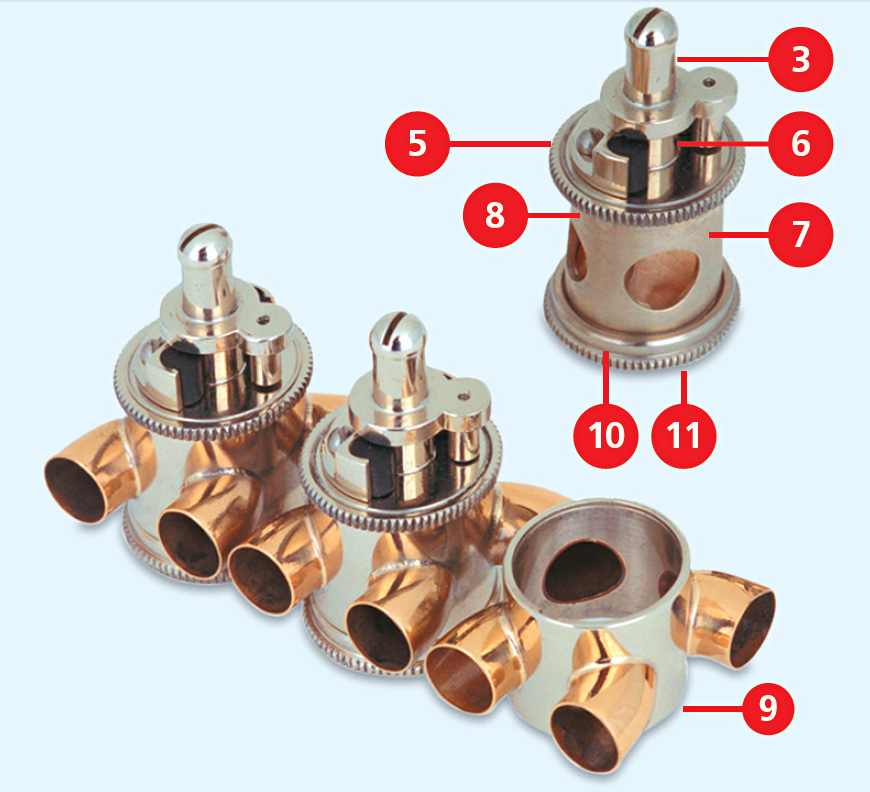

Lubricate the ATV-Valves on the bores on the top and the botton of the valve (see number 6) as follows:

Lubricate the valve bearings by applying oil first to the upper bearing pin (6) and then to the lower bearing pin by removing the bottom screw cap (11) on the lower bearing and applying the oil through the small pin hole on the bearing pin.

Removal and replacement of the ATV-Valves

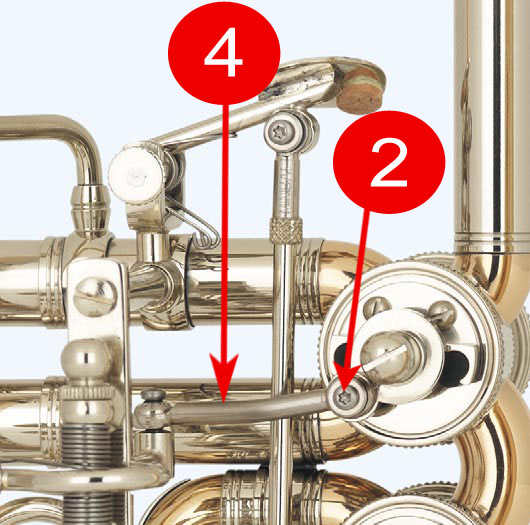

In order to remove the inner valve casing (7) from the outer valve casing (9), first remove the Minibal screw (2) from the stop arm (3) using the ![]()

Hold tightly onto the Minibal linkage when turning the screw since the valve is under tension due to the trigger spring.

- Remove the lower screw cap (11).

- Hold the valve (5) from above and push it out through the top.

- Rinse the valve (5) with lukewarm water and clean the valve casing (9) with the

- Apply a thin film of grease (Selmer Tuning Slide) on the valve casing (9).

It is best to rub the thin layer of grease on with your fingers. Take care that the grease does not get into the valve during removal and replacement.

- Simple and precise re-fitting of the valve casing is ensured by the adjusting pin (8).

- Now screw the lower valve cap (11) onto the outer valve casing (9) and insert the Minibal screw (2) through the Minibal-linkage (4) back into the stop arm (3).

Valves and casings (9) are important components of the instrument; take care that you go slow in order to prevent damage to them.

Valve Section Maintenance

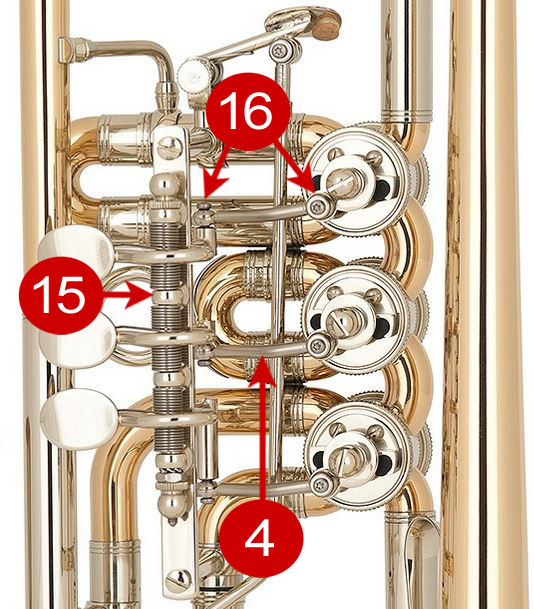

Oil the trigger axle (15) and the ball bearing (16) of the Miraphone Minibal-linkage (4) with ![]()

Allowing the joints to become too dry will cause unnecessary wear-and-tear.